Page 3 - ebook

P. 3

DPF Thermal Jet Cleaning Machine

What are the differences from the products

currently in use?

Initially there was the dry method of cleaning the DPF- the method preferred by the

diesel industry for its effectiveness; but Luster out-performs the existing equipments

used in the industry, by using a highly pressurized jet stream of air to clean the

substarte.

And because Luster does all this without the direct contact od flame with the substrate,

the result is a restored DPF with no thermal damage. Also due to the compact size it's

easy to move around and install ; and the machine operates without ant smoke, dust,

noises, or any seconary poluutant.

The construction is all stainless metal for optimal durability and corrosion resistance;

While its advanced touch-screen user interface provides a convenient, user-friendly

operation.

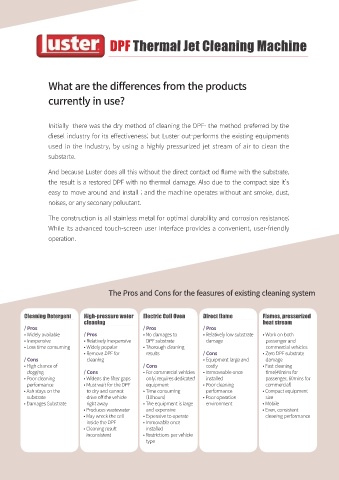

The Pros and Cons for the feasures of existing cleaning system

Cleaning Detergent High-pressure water Electric Coil Oven Direct flame Flames, pressurized

cleaning heat stream

/ Pros / Pros / Pros

• Widely available / Pros • No damages to • Relatively low substrate • Work on both

• Inexpensive • Relatively inexpensive DPF substrate damage passenger and

• Less time consuming • Widely popular • Thorough cleaning commercial vehicles

• Remove DPF for results / Cons • Zero DPF substrate

/ Cons cleaning • Equipment large and damage

• High chance of / Cons costly • Fast cleaning

dogging / Cons • For commercial vehicles • Immoveable once time(40mins for

• Poor cleaning • Widens the filter gaps only; requires dedicated installed passenger, 60mins for

performance • Must wait for the DPF equipment • Poor cleaning commercial)

• Ash stays on the to dry and cannot • Time consuming performance • Compact equipment

substrate drive off the vehicle (10hours) • Poor operation size

• Damages Substrate right away • The equipment is large environment • Mobile

• Produces wastewater and expensive • Even, consistent

• May wreck the cell • Expensive to operate cleaning performance

inside the DPF • Immovable once

• Cleaning result installed

inconsistent • Restrictions per vehicle

type